SAMBO' _[RECONFIGURED

Fabricator for Mara Marcu at the University of Virginia

Summer 2012

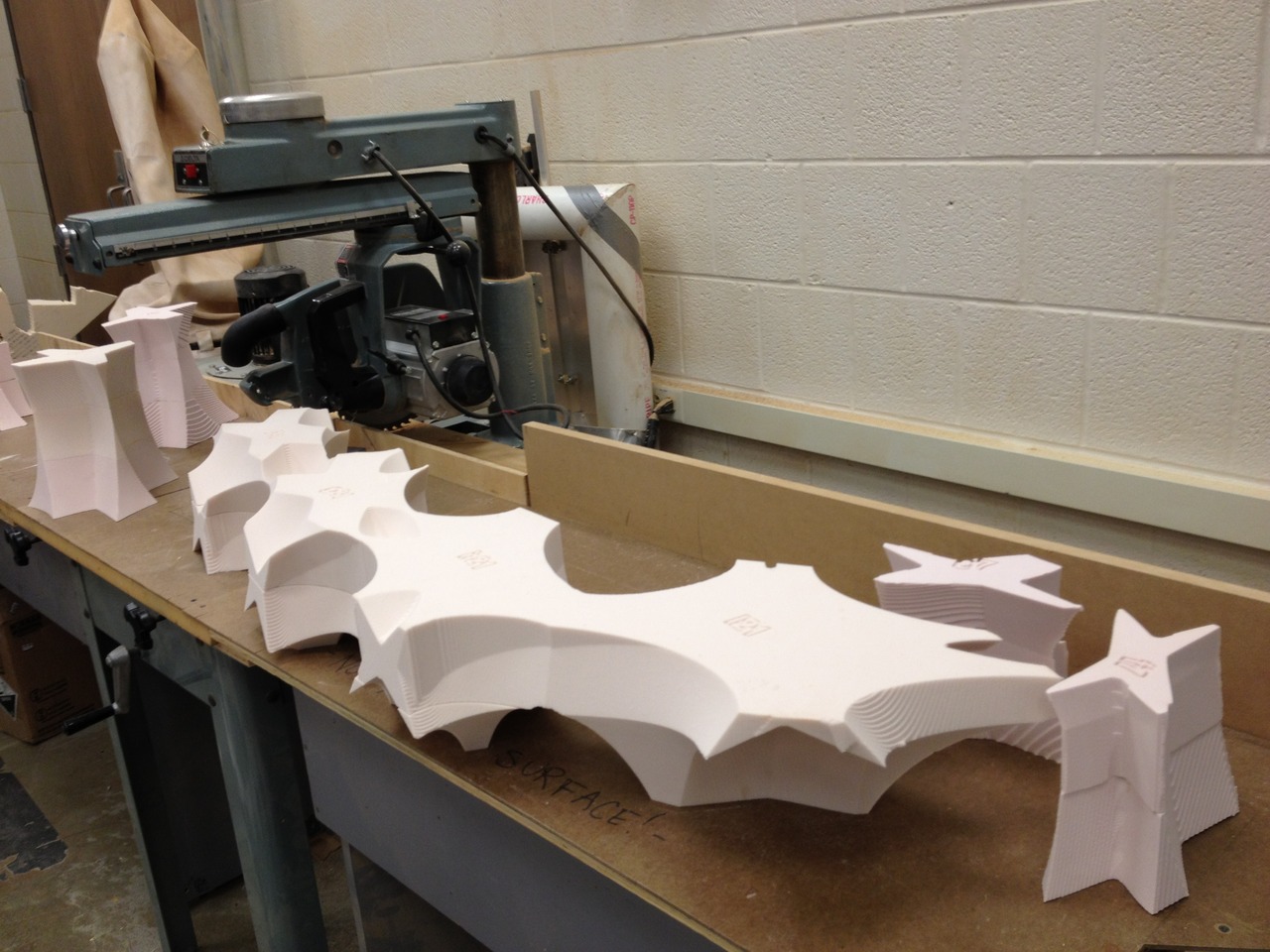

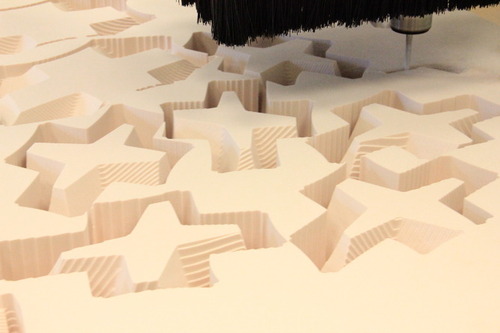

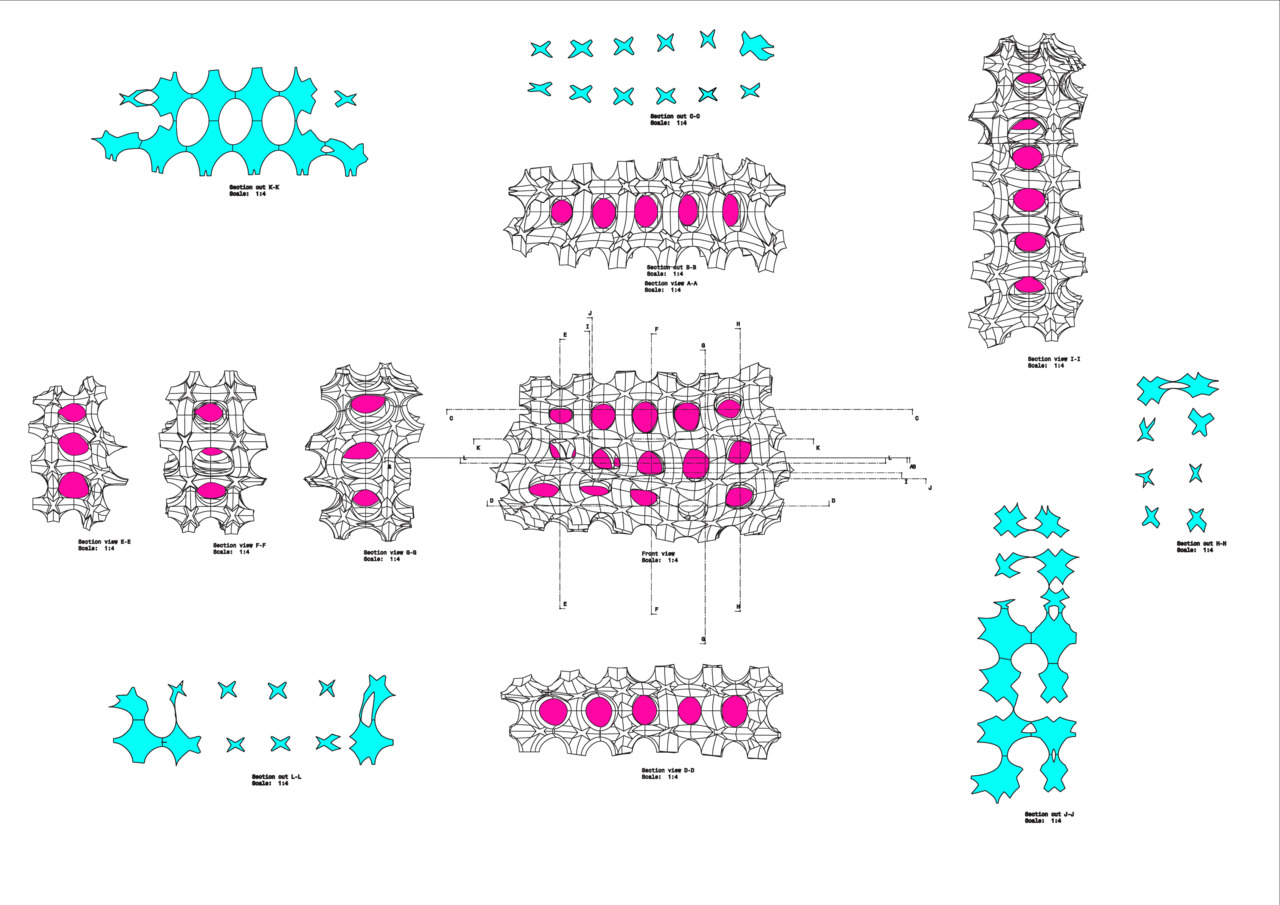

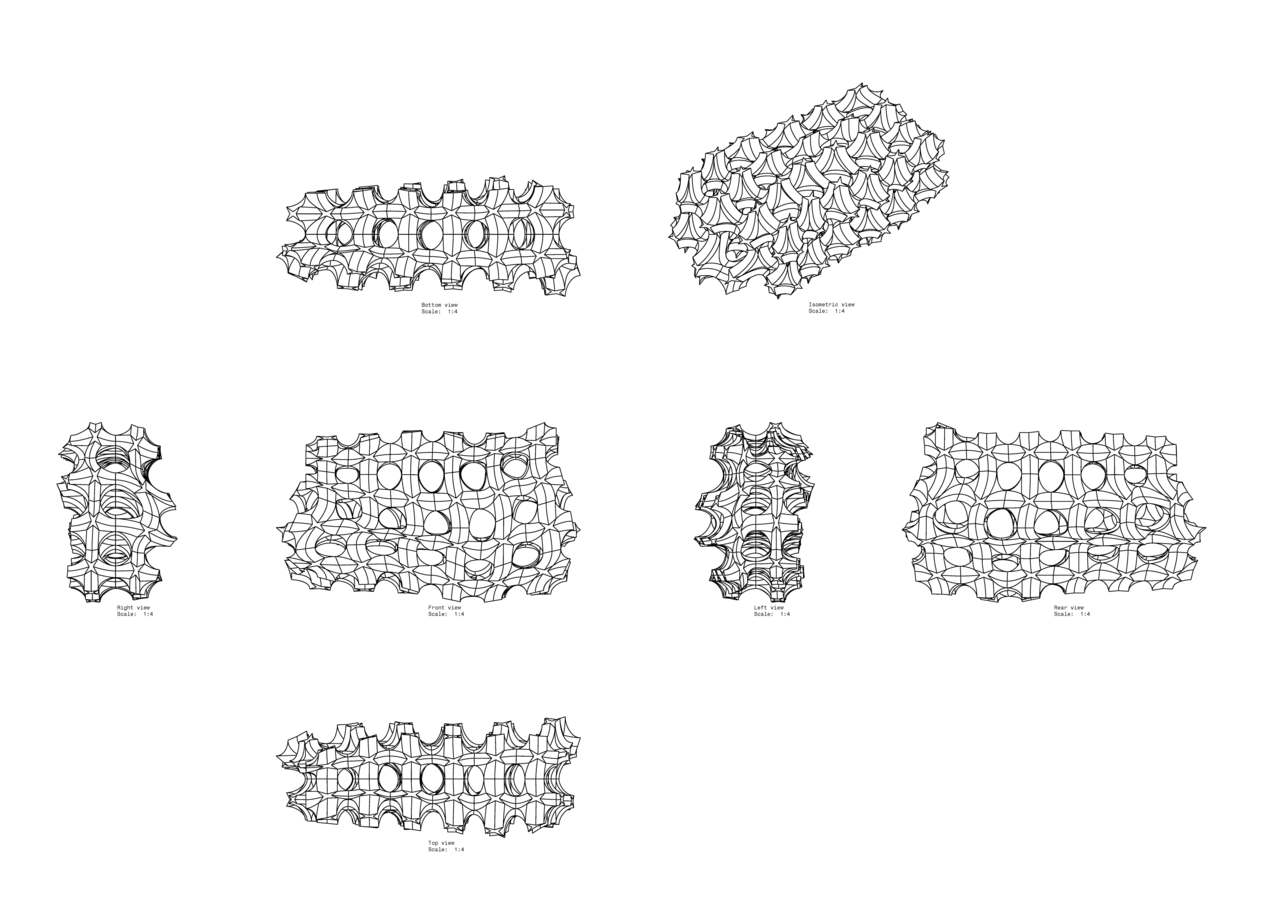

Sambo’_[Reconfigured investigates applications in architecture, tectonic details, interior furnishings and the realm of production. Designed with CATIA software, this installation pushes a 3-axis router to its limits with a unique undercut and variable module. Eight sheets of high density foam were flip milled and joined to create the final product. After fabricating the first wall, we were able to revisit the module slicing and tolerances in order to facilitate the second round of the fabrication process.

The first of the two walls was fabricated by splitting each module with non-orthogonal planes. This gives more fidelity to the intended form, but significantly exacerbated the final assembly process. Through this learning process, the second wall split the modules into simple planes, and used a much smaller step-over to facilitate sanding. However, some undercuts were unable to be routed because of the CNC's limits. This project pushed the limits of the 3-axis router, as well as experimented with post-processing required after machining.